Dynamic Simulation is the mathematical modeling of mechanical, thermal, fluid and acoustic systems undergoing time-varying behavior, such as harmonic, random or transient events. The simulation model can be based on explicit equations of motion, iterative methods, custom software, or commercial Finite Element Modeling (FEM) simulation programs such as LS-DYNA, ABAQUS and ANSYS. We are experts in the use of simulation software to solve difficult engineering problems involving dynamic inputs and behavior, and in the development of FEA Material Properties. Complex events such as mechanical shock, impact, vibration, and transient thermal or flow events can be modeled and analyzed, leading to valuable insights that improve product performance and quality.

Learn more about dynamic simulation at Wikipedia.

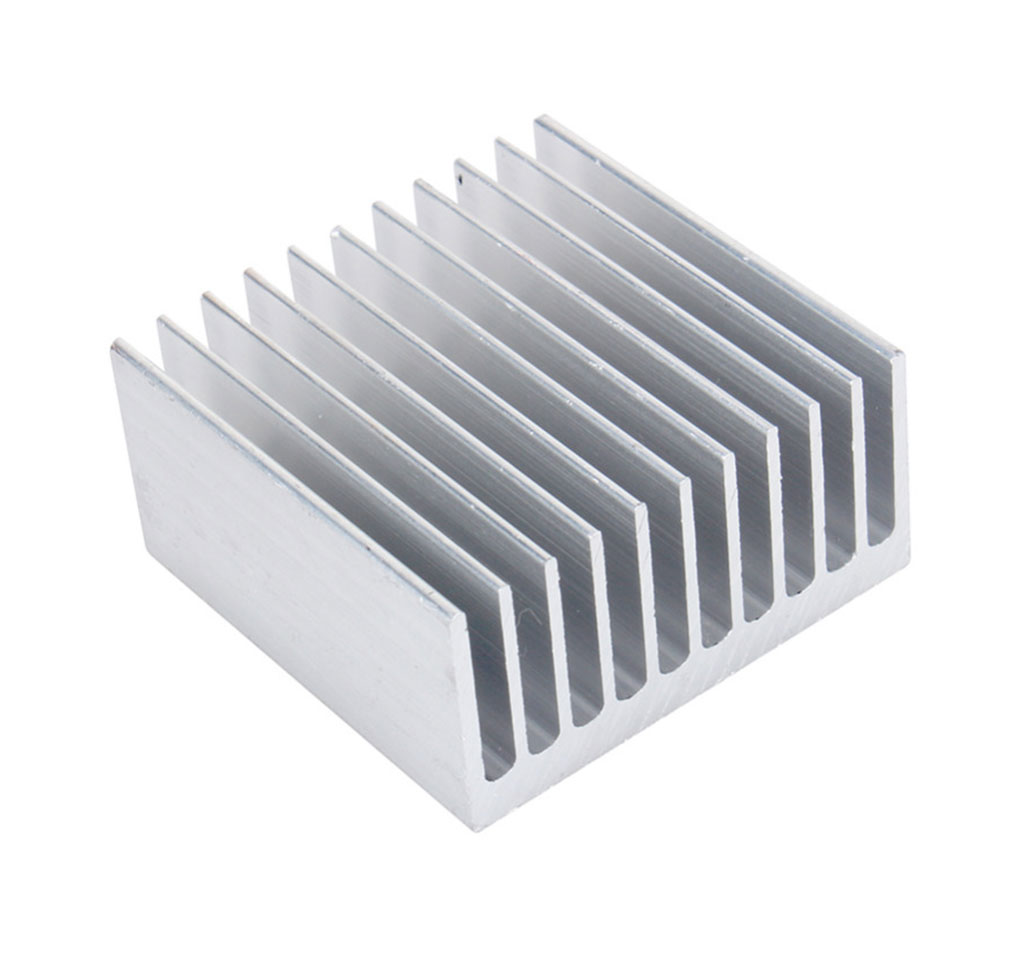

Heat Sink Convective Flow Analysis

Heat sinks are passive heat exchangers that are an important component of electrical systems, allowing them to operate at a reasonable temperature without overheating. They are used regularly in various industries and products ranging from consumer electronics to aerospace and defense applications.

A dynamic simulation of a heat sink was done using LS-DYNA Incompressible Computational Fluid Dynamics (ICFD) to understand its transient dynamic performance. Natural convection utilizes the movement of fluid caused by differences in density as the fluid heats up, but standard design calculations are based on steady-state systems. Modeling the airflow around the heat exchanger was critical in understanding its ability to dissipate heat from the heat source during the power-up cycle. The dynamic simulation was leveraged to optimize the heat exchanger’s performance and verify it would meet both its transient and steady-state performance specifications.

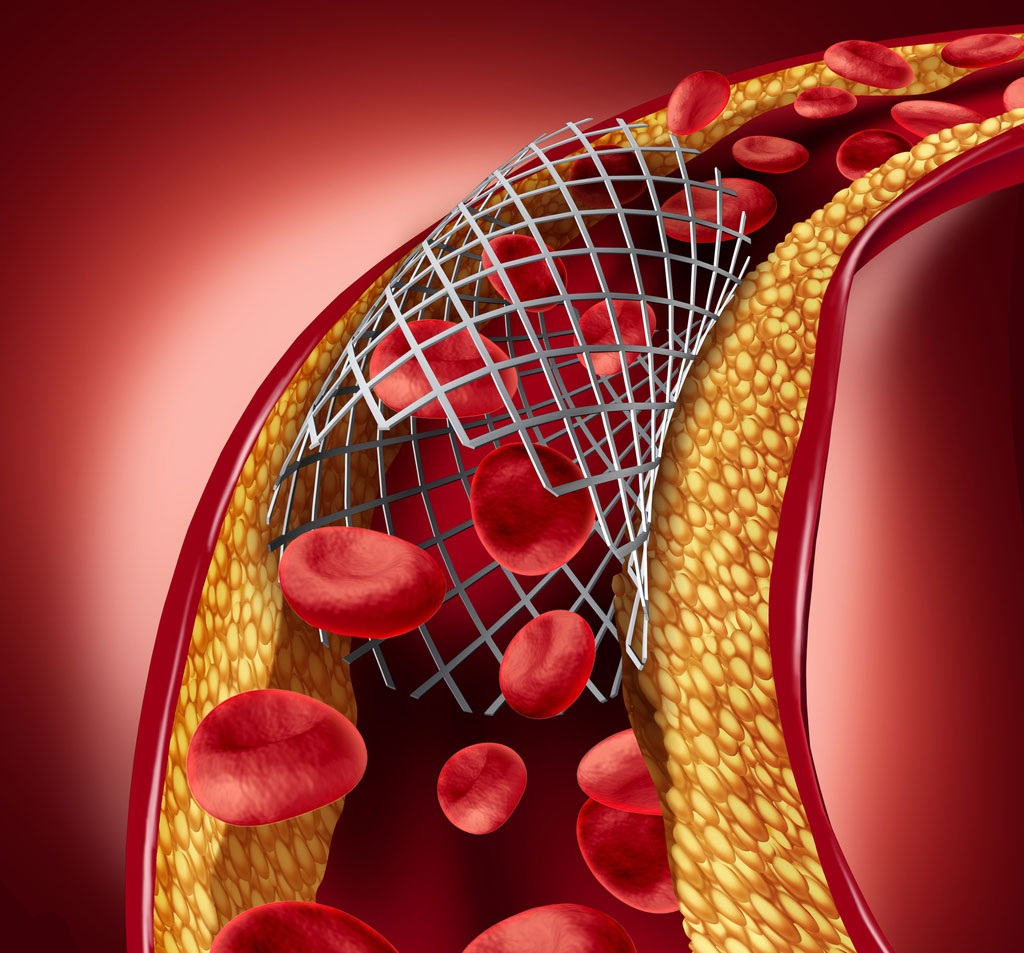

Cardiovascular Stent Dynamic Simulation

Modeling and Simulation is regularly used in biomedical and packaging industries to understand how complex systems will react under specified loading. For example, braided tubing and stent designs that may contain more than 500 unique fibers strand can be dynamically simulated using different materials and manufacturing methods to understand the performance characteristics of compression, tension, bending.

In this example, a dynamic simulation of a cardiovascular stent was done to predict its performance under transient pressure loading. The resulting analysis was utilized to better understand a proposed design concept and optimize its performance.

Process Equipment Support Frame

Design and development of manufacturing equipment and infrastructure is time-consuming and costly, especially when attempting to retrofit systems already placed in service. Problems can occur when frame vibration is ignored during the design phase, or when existing lines are sped up for greater throughput . Dynamic simulation can be utilized to understand the system response to harmonic loads created by motors, pumps and other rotating or reciprocating components. In this example, ANSYS was utilized to predict the frame's natural frequencies and mode shapes to assess whether mounted machinery would create excessive vibration. Based on the dynamic simulation results, the frame was redesigned to address all issues uncovered in the analysis.

Learn more about Virtual Manufacturing.