Kinetic Vision's failure analysis services utilize 3D CT Scanning, which is a powerful methodology that provides a fast and effective way to identify performance issues within parts and assemblies. Whether a component is slightly deformed or completely broken, failures can be identified by visual inspection or by comparing scan data to nominal CAD geometry. Our in-house Software Development Team can also automate many visual processes, allowing a great number of parts or locations within assemblies to be quickly and accurately inspected.

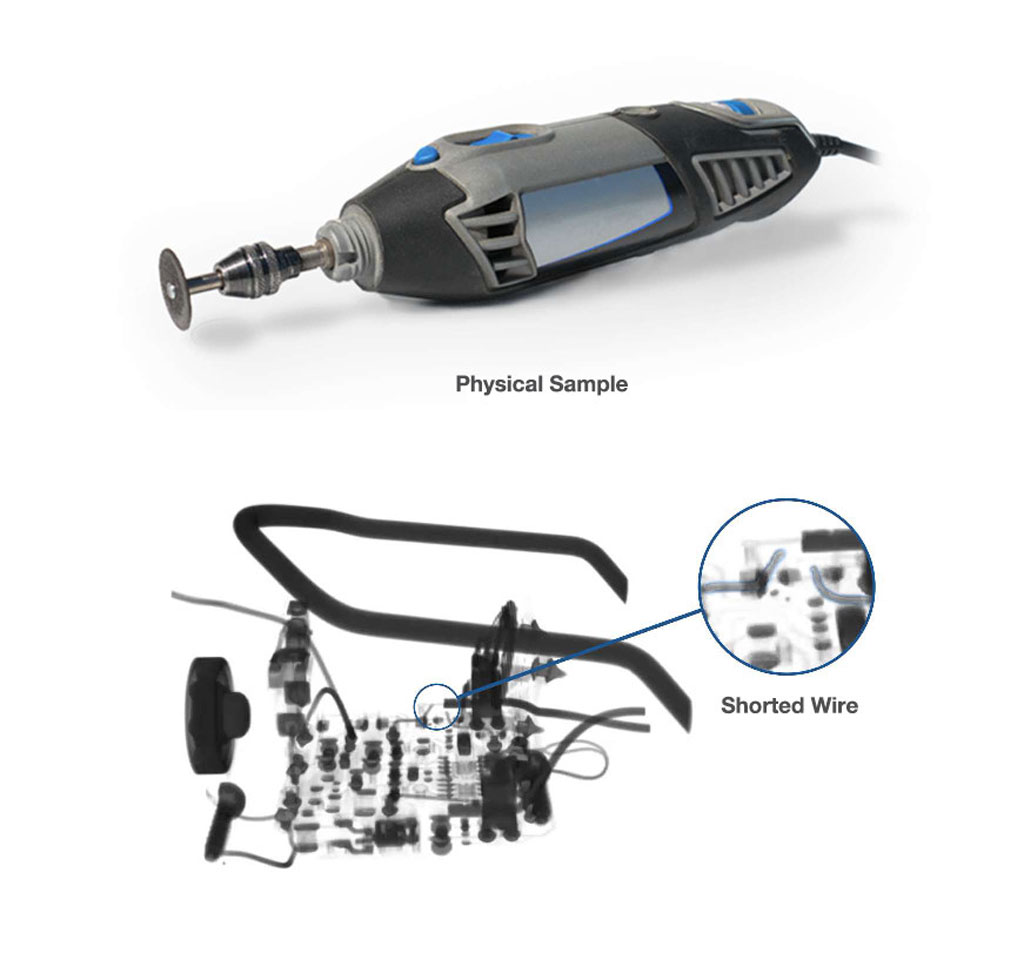

During product failure analysis, advanced imaging enables you to non-destructively see inside your product to quickly identify root cause issues. By utilizing these technologies and eliminating the need to “open” your product or device, the potential for compromising the system is minimized or eliminated, allowing for faster implementation of needed design or process modifications. In this example, a product with a tamper-resistant housing was investigated using CT X-ray scanning and a printed circuit board wiring issue was quickly identified.

Leak Failure Analysis

Industrial scanning is very useful as a failure diagnosis tool, especially with geometrically complex interfaces. In this example of our failure analysis services, leaking was occurring with a molded cap and bottle used to store a liquid. Much engineering goes into making a seemingly simple system like this, as small imperfections such as parting lines, excessive shrinkage or even mold surface finish can impact the sealing integrity. In this video, a sweep plane is used to visualize the sealing surface and the leak failure area is easily identified. With this understanding, dimensional and manufacturing changes are made to eliminate the problem.